PLENSETTM

Gas barrier type

PLENSETTM Gas Barrier Type is an innovative one-component epoxy resin adhesive

developed utilizing the advanced technological capabilities of Ajinomoto Fine-Techno.

This product maintains

the excellent low-temperature curing properties of the traditional PLENSET while incorporating additional

functionality as a gas barrier. It is designed to achieve a composition that is resistant to the infiltration of

water vapor and other gas components. Consequently, during sealing, it effectively prevents the entry of harmful

gases and moisture from the outside, significantly enhancing the performance and longevity of the sealed

parts.

This feature plays a crucial role in many fields, including electronic components, precision machinery,

sensor modules, and optical equipment.

Have you experienced these issues?

through airtight sealing

Here is the product that resolves these issues. PLENSETTM Gas barrier type

Examples and Applications

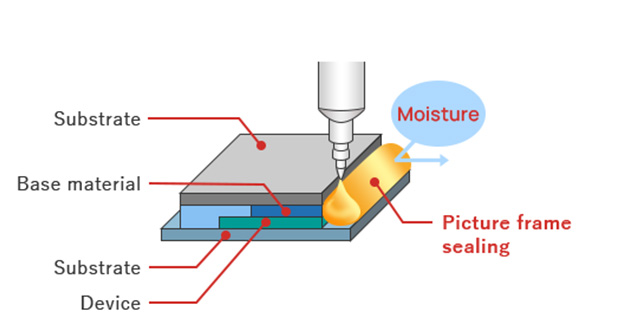

Picture frame sealing of devices

Hermetic sealing of vents and

through-holes

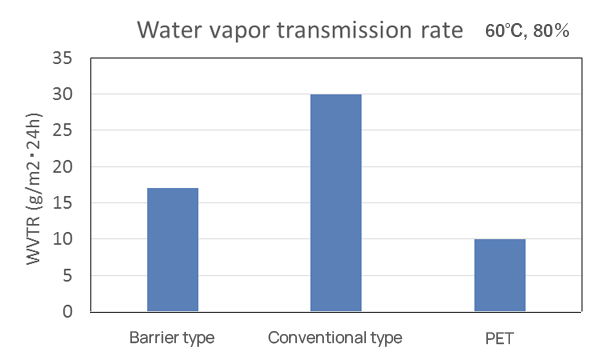

Comparison with conventional products

Characteristics

| Item | AES-110 | AES -210 | Conditions | ||

|---|---|---|---|---|---|

| Characteristics | Color tone and appearance | Pale yellow viscous liquid | Black viscous liquid | Visual inspection | |

| Viscosity | 7Pa・s | 9.8Pa・s | E-type viscometer 25degC,50rpm | ||

| Thixotropic index | 1.2 | 1.2 | E-type viscometer 25degC,5rpm/50rpm | ||

| Standard curing conditions | 70degC×60minutes | 90degC×60minutes | Hot air circulation oven | ||

| Properties of cured materials | Tensile lap shear strength | 13N/㎟ | 26N/㎟ | JIS K-685 (Steel plate) | |

| Glass transition temperature | 62degC | 100degC | TMA measurement | ||

| Thermal expansion coefficient | α1 | 40ppm | 72ppm | ||

| α2 | 136ppm | 117ppm | |||

| Water-vapor transmission ratio | 18-22g/m2・24h | 14-20g/m2・24h | 60degC, 80% JIS Z-0208 | ||