PLENSETTM

PLENSETTM

Gas barrier type

In-page Navigation

In addition to bonding, it also has an encapsulation function.

Through our proprietary formulation technology, we have achieved a composition that prevents the penetration of water vapor and other gaseous components, which helps maintain the performance of products to which it is applied.

Have you experienced these issues?

Easily encapsulating moisture-sensitive devices

case

01

Filling internal parts with gas and encapsulating

case

02

Need materials with high moisture-proof sealing capabilities

case

03

Here is the product that resolves these issues. PLENSETTM Gas barrier type

Adhesives with gas barrier properties

Protect the device from moisture and other gases

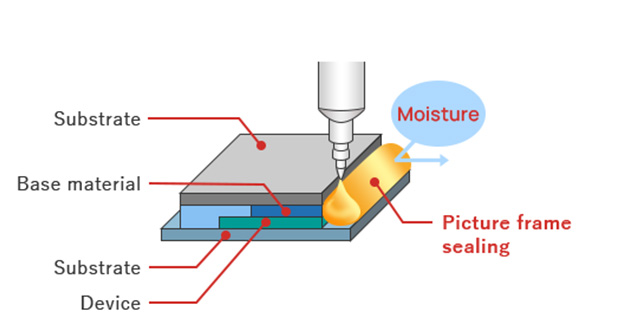

Picture frame sealing to protect the device from moisture

Feature

#1

Assembly and encapsulation of devices that require protection from moisture and other gases.

Feature

#2

Examples and Applications

Picture frame sealing of devices

Hermetic sealing of vents and through-holes

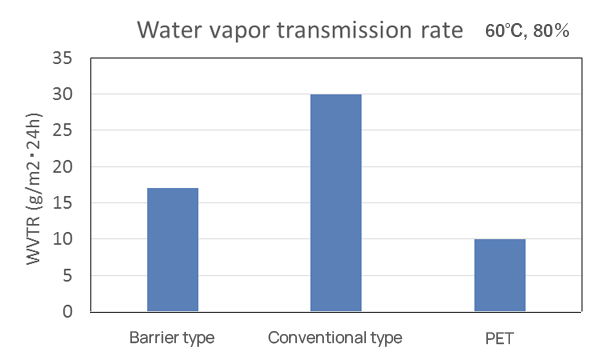

Comparison with conventional products

Characteristics

| Item | AES-110 | AES -210 | Conditions | ||

|---|---|---|---|---|---|

| Characteristics | Color tone and appearance | Pale yellow viscous liquid | Black viscous liquid | Visual inspection | |

| Viscosity | 7Pa・s | 9.8Pa・s | E-type viscometer 25degC,50rpm | ||

| Thixotropic index | 1.2 | 1.2 | E-type viscometer 25degC,5rpm/50rpm | ||

| Standard curing conditions | 70degC×60minutes | 90degC×60minutes | Hot air circulation oven | ||

| Properties of cured materials | Tensile lap shear strength | 13N/㎟ | 26N/㎟ | JIS K-685 (Steel plate) | |

| Glass transition temperature | 62degC | 100degC | TMA measurement | ||

| Thermal expansion coefficient | α1 | 40ppm | 72ppm | ||

| α2 | 136ppm | 117ppm | |||

| Water-vapor transmission ratio | 18-22g/m2・24h | 14-20g/m2・24h | 60degC, 80% JIS Z-0208 | ||

The data in this document are representative values, not standard values. The contents of this document are subject to change without notice.

Application process

Telephone or form inquiry

Inquire about customer issues, required characteristics

Propose and send samples for evaluation

Customer evaluation

Interview regarding results of evaluation

When it is difficult to use existing products

Consultation and consideration of development themes