PLENSETTM

Drop impact resistance type

What is the PLENSETTM Drop impact resistance type?

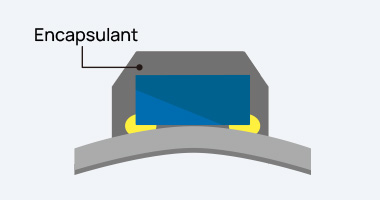

Generally, epoxy resin has the property of being hard and brittle, which limits its use in

applications requiring impact resistance and flexibility.

However, Ajinomoto Fine-Techno's PLENSETTM Drop

impact resistance type is a product that significantly transforms these conventional properties of epoxy

resins.

Developed using our proprietary advanced formulation technology, this adhesive combines low-temperature

curability

with flexibility as its core technology.

・With excellent flexibility, it can significantly improve stress relaxation and impact resistance.

・Achieves flexible bonding while maintaining high strength.

・Provides highly

reliable bonding that flexibly responds to dynamic loads such as bending and twisting.

Have you experienced these issues?

Here is the product that resolves these

issues.

PLENSETTM Drop impact resistance type

Application

It ensures reliability under harsh conditions such as smartphones requiring drop resistance and motors that generate vibrations, contributing to the long lifespan of components.

It can be used in a variety of situations.

Drop impact resistance through stress relaxation

It can be cured at a low temperature of 80degC, unparalleled for a one-component epoxy resin.

Vibration suppression and damping

Once cured, it gains a rubber-like elasticity, providing flexibility that is effective for stress alleviation as well as shock and vibration absorption.

Flexural resistance, low warpage

Due to its low elasticity, it has high peel strength and is effective for bonding dissimilar materials with large differences in linear expansion coefficients.

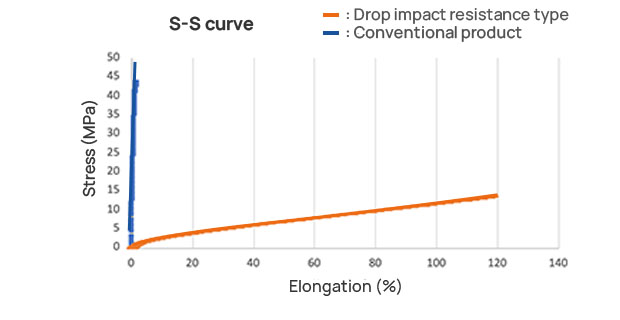

Flexibility test method for cured materials: JIS K7161 compliant

The drop impact resistance type exhibits a rubber-like flexibility.

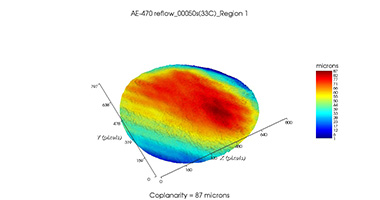

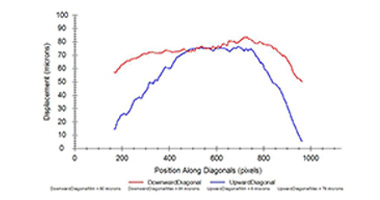

Warpage in molding wafers

Wafer: 12 inches, 0.8 mm thick Mold: 0.4 mm thick

Warpage does not occur with the drop impact

resistance type even when molding on one side of the wafer.

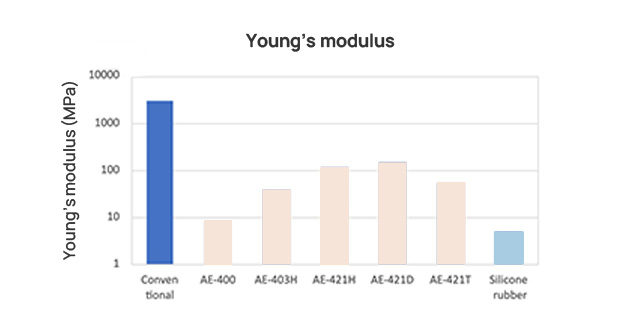

Characteristics

| Item | AE-400 | AE-403H | AE-421H | AE-421D | AE-421T | Conditions | |

|---|---|---|---|---|---|---|---|

| Characteristics | Appearance | Black viscous liquid | Black viscous liquid | Black viscous liquid | Black viscous liquid | Light yellow viscous liquid | Visual inspection |

| Viscosity | 10Pa・s | 7Pa・s | 16Pa・s | 10Pa・s | 21Pa・s | E-type viscometer 25degC,20rpm |

|

| Thixotropic index | 1.3 | 1.1 | 2.9 | 1.7 | 3.1 | E-type viscometer 25degC, 2rpm/20rpm |

|

| Standard curing conditions | 80degC×30minutes | Oven curing | |||||

| Properties of cured materials | Tensile lap shear strength | 14N/㎟ | 16N/㎟ | 12N/㎟ | 17N/㎟ | 29N/㎟ | Mild steel plate (polished) |

| 9.1N/㎟ | 11.4N/㎟ | 13.0N/㎟ | 12.6N/㎟ | 21.6N/㎟ | Nickel plating | ||

| 2.6N/㎟ | 4.8N/㎟ | 5.7N/㎟ | 4.8N/㎟ | 7.8N/㎟ | LCP | ||

| Young's modulus | 8MPa | 40MPa | 150MPa | 120MPa | 52MPa | JIS K-7161 | |

| Hardness | 86 | 70 | 70 | 70 | 61 | Shore D | |