PLENSETTM

Low temperature curing type

What is the PLENSETTM Low temperature curing type?

PLENSETTM Low temperature curing type is an innovative one-component epoxy resin

adhesive unparalleled in the market, capable of curing at the extremely low temperature of 60℃ in just 30 minutes.

This superior low-temperature curing characteristic makes it ideal for bonding heat-sensitive plastics, optical

components, and lenses, ensuring a wide range of applications across various environments.

Furthermore, the

PLENSETTM Low temperature curing type boasts a low cure shrinkage rate and a low coefficient of

expansion, resulting in minimal post-cure distortion. This feature makes it

exceptionally effective for bonding components and devices that require high precision.

PLENSETTM

Low temperature curing type can be tailored to various application methods. It can be adapted for point

dispensing, line dispensing, and full-surface dispensing, thereby enhancing the design flexibility of products and

achieving improved efficiency and accuracy in manufacturing processes.

It can achieve fast curing through medium-to-high temperature heating, simplifying the in-line

curing process. This capability boosts the throughput of production lines and maximizes production efficiency. An

efficient curing process maintains high product quality while supporting customers in reducing manufacturing costs

and delivering products in a timely manner, thereby contributing to solving customer challenges.

Have you experienced these issues?

Here is the product that resolves these issues. PLENSETTM Low temperature curing type

Application

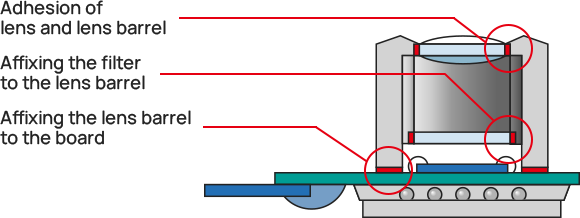

Assembly of camera modules for mobile devices

Adhesion around optical

lens

Adhesion to engineering plastics

Assembly and adhesion of heat-sensitive and precision parts

te

| Item | AE-901B | AE-901T-DA | Conditions | ||

|---|---|---|---|---|---|

| Characteristics | Color tone and appearance | Black viscous liquid | Black viscous liquid | Visual inspection | |

| Viscosity | 60Pa・s | 17Pa・s | E-type viscometer 25degC,20rpm | ||

| Thixotropic index | 1.1 | 2.0 | E-type viscometer 25degC,2rpm/20rpm | ||

| Gel time | 120seconds/80degC | 100seconds/80degC | Hot plate | ||

| Standard curing conditions | 60degC×30minutes | 60degC×30minutes | Hot air circulation oven | ||

| Properties of cured materials | Tensile lap shear strength | 16N/㎟ | 17N/㎟ | Mild steel plate | |

| 2.7N/㎟ | 3.4N/㎟ | Polycarbonate | |||

| Glass transition temperature | 55degC | 44degC | TMA measurement | ||

| Thermal expansion coefficient | α1 | 50ppm | 60ppm | ||

| α2 | 80ppm | 150ppm | |||