UV and Thermal Combination Type PLENSETTM

What is PLENSETTM UV and Thermal Combination Type?

PLENSETTM UV and Thermal Combination Type is an innovative epoxy resin adhesive

that, in addition to the excellent low-temperature curing properties of the conventional

PLENSETTM, newly incorporates a UV (ultraviolet) temporary fixing function. This unique

combination makes it ideal for assembling devices and modules where positional accuracy before and after

curing is extremely important or where active alignment is required.

Furthermore, PLENSETTM UV

and Thermal Combination Type possesses the same high flexibility as PLENSETTM Flexible Type. This

flexibility enhances impact resistance and stress relaxation, increasing the strength of the joints. By

providing flexible bonding, it enhances the reliability and durability of precision instruments and

electronic components.

Have you experienced these issues?

Here is the product that resolves these issues. PLENSETTM Narrow gap curing type

Application

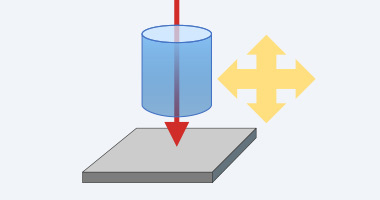

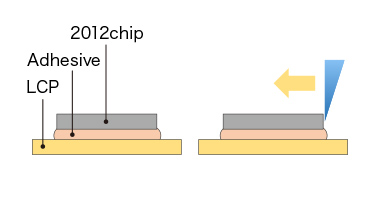

- Bonding parts that require alignment, such as active alignment

- Bonding dissimilar materials and difficult-to-bond substrates (engineering plastics like LCP and PA9T, metals like gold and nickel)

- Bonding and joining flexible substrates and components that require flexibility, such as displays

It can be used in a variety of situations.

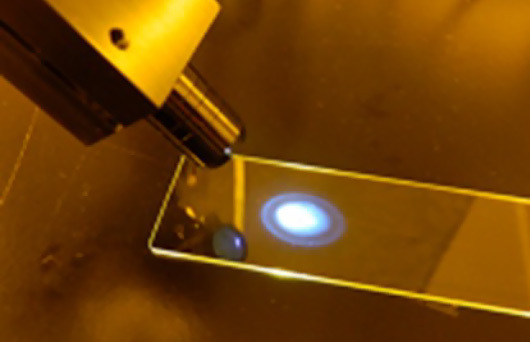

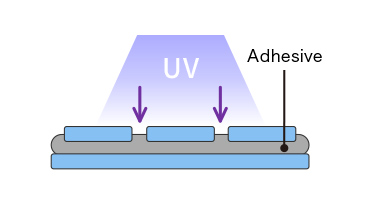

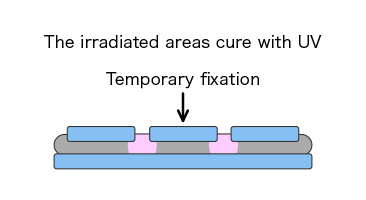

Temporary Fixation and Alignment

Temporary fixation and alignment are possible through UV curing.

Drop Impact Resistance through Stress Relaxation

After curing, it becomes a rubber-like elastomer, providing flexibility that is effective for drop impact resistance.

Vibration Suppression and Damping

After curing, it becomes a rubber-like elastomer, providing flexibility that is effective for stress relaxation and absorbing shocks and vibrations.

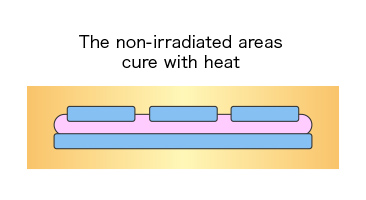

Image of temporary fixation

Product details

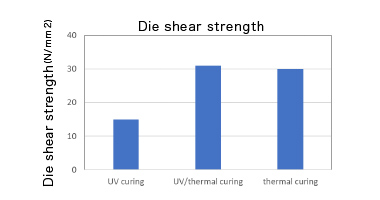

Die shear strength

Characteristics

| Item | DC-412B | 条件 | |

|---|---|---|---|

| Characteristics | Appearance | Black viscous liquid | Visual inspection |

| Viscosity | 4Pa・s | E-type viscometer,25℃, 50rpm | |

| Thixotropic index | 1.3 | E-type viscometer,25℃, 5rpm/50rpm | |

| Standard curing conditions | 3000mJ/㎠+ 80degC×30min |

UV-LED,365nm Oven curing |

|

|

Properties of cured materials |

Tensile lap shear strength | 20N/㎟ | Mild steel plate (polished) |

| Glass translation temperature |

25degC | TMA | |

| CTE α1 | 76ppm | ||

| CTE α2 | 187ppm | ||

| Young’s modulus | 400MPa | JIS K-7161 | |

| Elongation | 108% | ||

| Cure Shrinkage | 5.1% | Calculated from Specific Gravity | |