PLENSETTM

PLENSETTM

No particle type

In-page Navigation

What is the PLENSETTM No particle type?

The PLENSETTM No particle type (AE-700) is a fully liquid one-component adhesive that contains no powder components.

Since the resin and curing agent are dissolved into a liquid, penetration into narrow gaps and complete curing is possible.

Have you experienced these issues?

Uncured separation occurs when pouring into narrow gaps.

case

01

To make adhesive thickness as thin as possible, even down to micron scale

case

02

Thin-film coating on material surface

case

03

Here is the product that resolves these issues. PLENSETTM No particle type

The adhesive is a no particle type that does not contain any powder components.

Feature

#1

Enables impregnation bonding to narrow gaps.

Feature

#2

The adhesive thickness can be reduced to the level of the surface roughness of the adhesive material.

Feature

#3

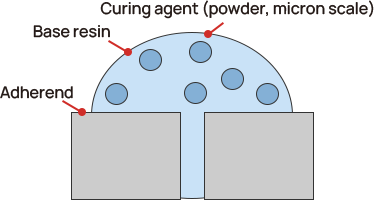

Solid dispersion one-component type (general products)

Resin permeates, but curing agent does not (separation) Permeated area is uncured

Permeated area is uncured

Permeated area is uncured

Permeated area is uncuredNo particle one-component type AE-700

Uniformity of the primary and curing agents even in permeated areas Complete curing even in narrow gaps

Complete curing even in narrow gaps

Complete curing even in narrow gaps

Complete curing even in narrow gapsApplication

Impregnation bonding into gaps and narrow areas after assembly of parts

Adhesion, fixing of parts attached with screws

Encapsulation of threaded coils, impregnation bonding

Areas where the thinnest possible adhesive thickness is desired

Characteristics

| Item | AE-700 | Conditions | ||

|---|---|---|---|---|

| Characteristics | Color tone and appearance | Brown clear liquid | Visual inspection | |

| Viscosity | 11Pa・s | E-type viscometer, 25degC、5rpm | ||

| Thixotropic index | 1.1 | E-type viscometer, 25degC、2rpm/20rpm | ||

| Gel time | 18minutes/120degC | Hot plate | ||

| Standard curing conditions | 120degC×30minutes | Hot air circulation oven | ||

| Properties of cured materials | Tensile lap shear strength | 22N/㎟ | JIS K-6850 (Steel plate) | |

| Glass transition temperature | 53degC | TMA measurement | ||

| Thermal expansion coefficient | α1 | 75ppm | ||

| α2 | 185ppm | |||

The data in this document are representative values, not standard values. The contents of this document are subject to change without notice.

Application process

Telephone or form inquiry

Inquire about customer issues, required characteristics

Propose and send samples for evaluation

Customer evaluation

Interview regarding results of evaluation

When it is difficult to use existing products

Consultation and consideration of development themes