PLENSETTM

Narrow gap curing type

What is the PLENSETTM narrow gap curing type?

PLENSETTM Impregnation Adhesive Type is a one-component epoxy resin adhesive that

applies an innovative curing system in a fully liquid form.

It ensures uniform curing even in narrow gaps or

with small amounts of application, preventing curing defects due to component separation and enabling stable

adhesion.

By heating within a temperature range of 80°C to 120°C, it fully cures in approximately 30 to 60

minutes. This temperature condition and curing speed are highly flexible in the manufacturing process,

accommodating various production takt times.

The outgassing from the cured material is extremely low, making it

ideal for assembling precision machinery that requires high low-outgassing properties. It is particularly

effective in applications where minimizing the impact of outgassing is crucial, such as HDD

components.

PLENSETTM Impregnation Adhesive Type has an excellent pot life (usable time) at room

temperature, maintaining stable dispensing processes even during long work periods or mass production. This

characteristic ensures uniform quality in assembly work that requires high precision, contributing to improved

product reliability.

Have you experienced these issues?

Here is the product that resolves these issues. PLENSETTM Narrow gap curing type

Application

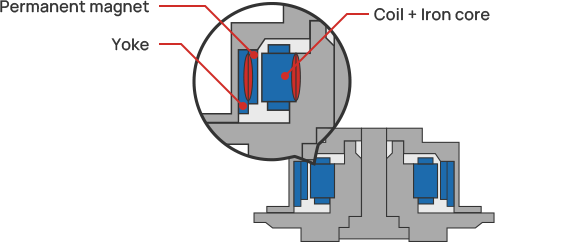

HDD spindle motor assembly

Motor magnet adhesion

Characteristics

| Item | AE-403H | AE-740 | AE-770SF | Conditions | ||

|---|---|---|---|---|---|---|

| Characteristics | Color tone and appearance | Black viscous liquid | Black viscous liquid | Red viscous liquid | Visual inspection | |

| Viscosity | 7Pa・s | 13Pa・s | 7Pa・s | E-type viscometer, 25degC、50rpm | ||

| Thixotropic index | 1.1 | 1.3 | 1.1 | E-type viscometer, 25degC、5rpm/50rpm | ||

| Gel time | 65seconds/80degC | 22seconds/80degC | 12seconds/90degC | Hot plate | ||

| Standard curing conditions | 80degC×30minutes | 80degC×60minutes | 90degC×60minutes | Hot air circulation oven | ||

| Properties of cured materials | Tensile lap shear strength | 14N/㎟ | 18N/㎟ | 18N/㎟ | JIS K-6850 (Steel plate) | |

| Glass transition temperature | 35degC | 51degC | 100degC | TMA measurement | ||

| Thermal expansion coefficient | α1 | 71ppm | 94ppm | 70ppm | ||

| α2 | 192ppm | 179ppm | 159ppm | |||