Latent curing agent AJICURETM

What is AJICURETM?

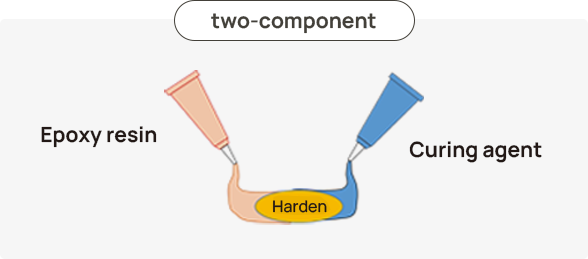

AJICURETM is a latent curing agent and accelerator specifically for use with one-component epoxy resins developed by Ajinomoto Fine-Techno.

It is also widely used abroad under the name AJICURETM.

It is applied in various fields such as electronic component and automobile part bonding, powder coatings, and composite materials such as prepreg.

Ajinomoto Fine-Techno's low temperature curing technology

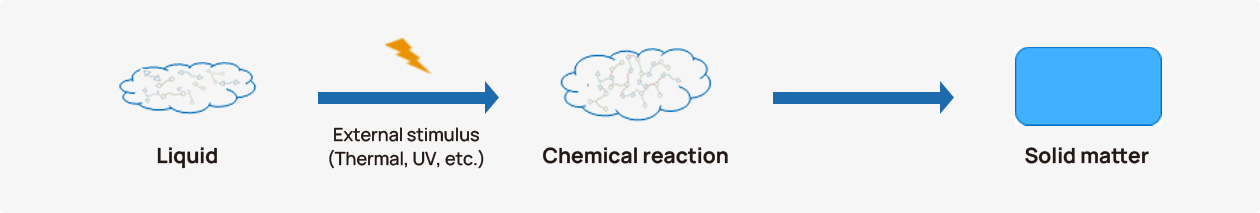

Epoxy resin curing

Chemical reaction type: Curing occurs when a chemical reaction is triggered by some external stimulus.

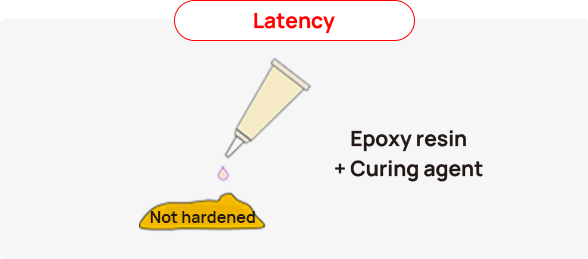

Latency

It is extremely difficult to achieve both storage stability and low-temperature curability even with potentiality.

Ajinomoto Fine-Techno's low temperature curing technology

Added value provided by low temperature curing technology

Increased productivity

It improves productivity and reduces environmental impact by lowering production temperature and shortening production time.

New material combinations

It enables materials that could not be used before due to their low heat resistance to be combined, resulting in completely new devices.

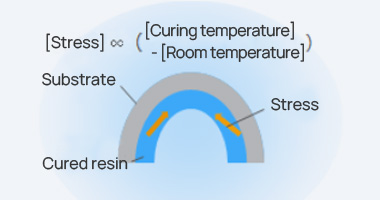

Improved adhesion reliability

Lowering the curing temperature alleviates internal stress due to cooling shrinkage, resulting in high adhesive strength and crack prevention.

Have you experienced these issues?

Here is the product that resolves these issues.

Latent curing agent AJICURETM

Feature

Adhesives for electronic materials, Encapsulant, Film products

Adhesives for automobiles, Structural materials

Prepreg, Composite materials such as filament winding

Powder paint

Benefits of introduction

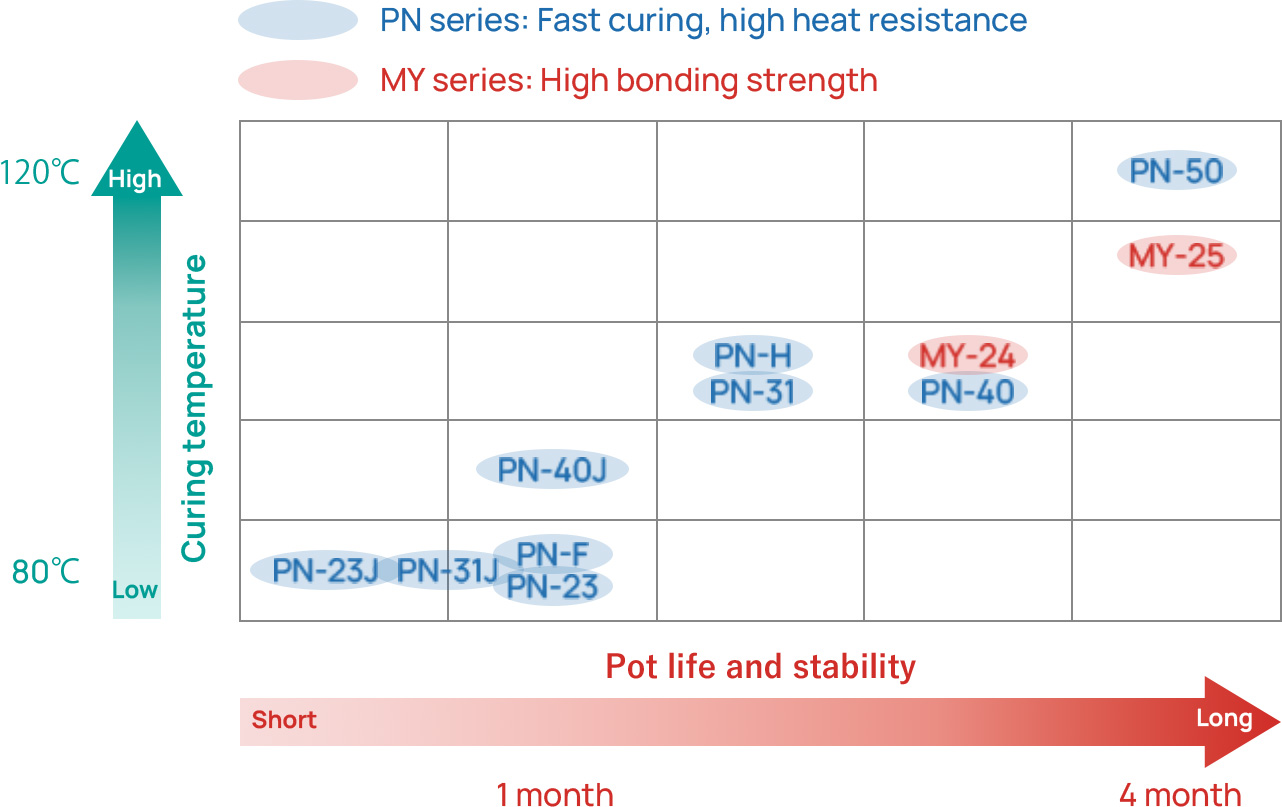

As a latent curing agent, it effectively balances short curing time and pot life for low-temperature curing.

The PN and MY series can be used to create one-component epoxy resin compounds with superior curing properties and long shelf life.

We can also propose applications for resin compounds that can be stored at room temperature in environments where refrigerated storage is difficult.

As a curing accelerator for dicyandiamide, etc., it is also highly effective in lowering the curing temperature and improving the curing speed.

The hydrazide series has an extremely low curing temperature compared to general hydrazide compounds, and offers a variety of unique physical characteristics such as transparency and flexibility.

Feature

Lineup

It has the following lineup and is applied in a wide range of fields such as bonding of electronic components and automotive parts, powder coating, and composite materials such as prepreg.

PN and MY series: Amine adducts

Hydrazide series: Dihydrazide compounds

AH series: Complex system

AJICURETM PN and MY series

| Classification | Variety | Volume added(phr) | Curing conditions | Life | Features |

|---|---|---|---|---|---|

| Amine adducts | PN-23 | 20 | 80degC×30 minutes | 1 month | Fast curing at low temperature, High heat resistance |

| PN-H | 20 | 100degC×30 minutes | 2 months | Modified PN-23 for longer pot life | |

| PN-31 | 20 | 100degC×30 minutes | 2 months | Better better storage stability in bisphenol F epoxy than PN-H | |

| PN-40 | 20 | 100degC×30 minutes | 3 months | Better better storage stability in bisphenol F epoxy than PN-H | |

| PN-50 | 20 | 120degC×30 minutes | 4 months | Good stability at high temperatures | |

| PN-F | 20 | 80degC×30 minutes | 1 month | PN-23 low chlorine grade | |

| PN-23J | 20 | 80degC×30 minutes | 2 weeks | Micropulverized PN-23, Good low temperature curing properties | |

| PN-31J | 20 | 80degC×30 minutes | 3 weeks | Micropulverized PN-31 | |

| PN-40J | 20 | 90degC×30 minutes | 1 month | Micropulverized PN-40, Longer life | |

| MY-24 | 25 | 100degC×60 minutes | 3 months | Better storage properties, High adhesive strength | |

| MY-25 | 25 | 110degC×60 minutes | 4 months | Modified MY-24 for longer shelf life |

Comparison of the characteristics of AJICURETM

AJICURETM hydrazide, AH Series

| Classification | Variety | Volume added(phr) | Curing conditions | Life | Features |

|---|---|---|---|---|---|

| Hydrazide | VDH | 41 | 110degC×60 minutes | 1 month | Water soluble, Good transparency |

| VDH-J | 41 | 110degC×60 minutes | 1 month | Micropulrerized VDH | |

| UDH | 48 | 130degC×60 minutes | 3 months | Low calorification, High peel strength | |

| UDH-J | 48 | 130degC×60 minutes | 3 months | Micropulverized UDH | |

| Complex system | AH-123 | 45 | 120degC×30 minutes | 1 month | Flexibility added |

| AH-203 | 25 | 90degC×60 minutes | 1 month | High shear stability, High peel strength | |

| DICY | AH-154 | 9 | 150degC×60 minutes | 3 months | High dispersion, Good curing properties |

| AH-162 | 11 | 150degC×60 minutes | 3 months | High dispersion, Long life in high temperature |

AJICURETM hydrazide series

Transparent, colorless cured material

High Tg cured material

White Solid (powder)

Molecular weight: 314g/mol

Active hydrogen equivalent: 78.5g/eq.

Melting point: 120degC

Solubility: More than 100g (For 100g of water)

High peel strength

Low elasticity cured product

White Solid (powder)

Molecular weight: 366g/mol

Active hydrogen equivalent: 91.5g/eq.

Melting point: 160degC

Solubility: Less than 1g (For 100g of water)

Examples and Applications

Realization of one-component epoxy resin compounds with superior low temperature curing properties