PLENSETTM

High reliability type

What is the PLENSETTM High reliability type?

High adhesive strength and toughness

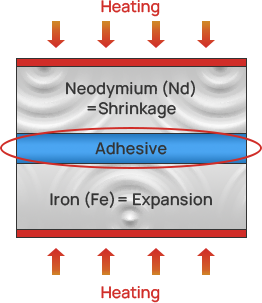

Adhesive strength is high against both tensile shear and peeling over a wide temperature range, making it ideal for structural bonding and the bonding of dissimilar materials.

Particularly flexible varieties can be used for bonding in places where stress is generated, such as neodymium magnets.

Long-term reliability

In terms of heat cycle, moisture resistance, and high-temperature aging, it meets the required degree of durability for small-motor magnets for use in automobile.

High heat-resistant varieties are particularly reliable and exhibit superior adhesive retention in harsh environments.

Fast curing

In addition to curing using a standard oven, instantaneous heating methods such as high-frequency induction heating and IR curing can also be used.

Have you experienced these issues?

Here is the product that resolves these issues. PLENSETTM High reliability type

Application

Bonding and joining of dissimilar materials such as engineering plastics and metals

Bonding of neodymium magnets for motors

Fixing coil components

High-reliability applications such as optical communication components, semiconductor packaging, and encapsulation